Introduction

Whenever my friends ask about my profession, I tell them I am a quality engineer. However, many people don’t know what a quality engineer actually does. Unlike more straightforward job titles, the role of a quality engineer isn’t immediately clear to everyone. Even my mom, familiar with my job title, often sends me job postings that don’t match my skill set. The truth is, many industries need quality professionals. In this article, I’ll explain how I got into this role and the skills required to excel in it.

How I Got into This Profession

After graduating with a degree in Chemistry, I initially aimed to secure a research job or a position conducting experiments in a lab setting. However, I quickly discovered that R&D positions were scarce. Instead, most of my job interviews focused on roles that involved testing products in quality-controlled laboratories to ensure they met specific standards. These opportunities were in various industries, including food, medical devices, pharmaceuticals, and cosmetics.

As a new graduate, I wasn’t fully aware of the purpose or significance of quality control roles. However, I decided to accept a position that closely aligned with my studies—a lab technician/QS technician role at a medical device company. This company specialized in renal therapy and dialysis products, which are critical for patients with kidney failure due to several reasons such as chronic kidney disease, acute kidney injury, diabetes, and more. Ensuring the quality of these products is essential as they can directly impact patients’ lives. The company was regulated by the FDA and ISO certified, with every manufacturing step revolving around quality control. This included the inspection of raw materials, packaging, manufacturing processes, and distribution to ensure the highest standards were maintained.

Understanding the Role of a Quality Engineer

At this point, you might have a general idea of what a quality engineer does: maintaining the quality of products, improving processes, and ensuring the accuracy of tests. However, the job duties extend far beyond these tasks. Quality engineering is a broad field that involves maintaining the company’s quality management system. This encompasses a wide range of responsibilities, including developing and implementing quality control procedures, conducting audits, analyzing data to identify areas for improvement, ensuring compliance with regulatory standards, and training staff on quality standards. In essence, a quality engineer plays a crucial role in ensuring that every aspect of the production process meets the highest standards of quality and safety.

Climbing the Career Ladder

While working as a lab technician at the company, I acquired several essential skills related to quality control. These included nonconformance investigation, corrective and preventive actions (CAPA), writing procedures, validation for test methods, and understanding ISO standards related to medical devices and Six Sigma methodologies. These skills enabled me to climb the career ladder from a lab technician to a lead analyst, and eventually to a quality engineer. Additionally, building good relationships with colleagues and supervisors is critical. Demonstrating strong work ethic and professionalism ensures that when job opportunities or promotions arise, you are considered first and have advocates who will vouch for you.

However, the focus on quality isn’t limited to medical device or pharmaceutical companies. Quality is crucial across all industries as it directly impacts consumer satisfaction and business success. For instance, you wouldn’t want a car that isn’t reliable, to wait months for a shipment that ends up at the wrong address, or to find defects in your everyday phone. Quality control ensures these scenarios are avoided, which is why most companies, regardless of their sector, require quality professionals. Quality is the cornerstone of a successful business, ensuring reliability, efficiency, and customer satisfaction in every product and service offered.

Key Responsibilities of a Quality Engineer

Quality Management System (QMS) Maintenance:

- Develop, implement, and maintain the company’s QMS to ensure compliance with industry standards and regulations, such as ISO 9001, ISO 13485 (for medical devices), or other relevant standards.

Process Improvement:

- Identify areas for process improvement using methodologies like Six Sigma, Lean, and other quality improvement tools. Implement changes to enhance efficiency, reduce waste, and improve product quality.

Product Testing and Validation:

- Design and conduct tests to ensure products meet quality and safety standards. Validate test methods and equipment to ensure accuracy and reliability.

Nonconformance Management:

- Investigate nonconformance issues, determine root causes, and implement corrective and preventive actions (CAPA) to prevent recurrence.

Audits and Compliance:

- Conduct internal audits to ensure compliance with quality standards and regulatory requirements. Prepare for and facilitate external audits by regulatory bodies or customers

Documentation and Reporting:

- Maintain detailed records of quality control processes, test results, and other quality-related activities. Generate reports to communicate findings and recommendations to management

Supplier Quality Management:

- Evaluate and monitor suppliers to ensure they meet quality standards. Conduct supplier audits and manage supplier-related nonconformance issues.

Training and Support:

- Provide training and support to staff on quality standards, procedures, and best practices. Ensure that employees understand and adhere to quality requirements

Risk Management:

- Identify potential risks in the production process and develop strategies to mitigate them. Use tools like Failure Mode and Effects Analysis (FMEA) to assess and address risks

Customer Satisfaction:

- Address customer complaints and quality issues. Implement feedback mechanisms to improve product quality and customer satisfaction

Essential Skills for Quality Engineers

- Statistical Analysis and Data Interpretation:

- Ability to analyze data using statistical tools to identify trends and variances. Proficiency in software like Minitab, JMP, or other statistical analysis tools is often required. Companies frequently require quality engineers to develop and maintain monitoring plans for processes, such as defect analysis, nonconformance rates, complaint rates, and first pass yield. These monitoring plans help in reviewing performance and identifying potential areas for improvement or underlying problems.

- Knowledge of Quality Standards and Regulations:

- You need to understand the ISO standards and regulations associated with the industry you work in. Ensuring that the company complies with these standards and making adjustments if there are any updates or new amendments to the regulations or industry standards is crucial. This involves staying current with regulatory changes and integrating them into the company’s quality management systems

- Quality Management Systems (QMS):

- Experience in developing, implementing, and maintaining QMS. Proficiency in tools and methodologies used in QMS, such as CAPA, audits, and document control.

- Process Improvement Techniques:

- Expertise in methodologies such as Six Sigma, Lean, Kaizen, and other process improvement tools. Ability to implement these techniques to enhance efficiency and reduce waste.

- Testing and Validation:

- Skills in designing and conducting tests to validate product quality and reliability. Knowledge of test equipment and validation protocols, such as Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) for equipment or processes. This also includes Computer System Validation (CSV) and test method validation.

- Nonconformance Management:

- Ability to investigate nonconformance issues, determine root causes, and implement corrective and preventive actions (CAPA).

- Risk Management:

- Proficiency in identifying and mitigating risks using tools like Failure Mode and Effects Analysis (FMEA) and Risk Priority Number (RPN) calculations.

Soft Skills

- Attention to Detail:

- Meticulous attention to detail to identify defects, errors, and areas for improvement in processes and products.

- Problem-Solving:

- Strong problem-solving skills to address quality issues effectively and implement solutions that prevent recurrence.

- Communication:

- Excellent communication skills to convey quality standards, procedures, and expectations to team members and stakeholders. Ability to write clear and concise reports and documentation.

- Teamwork and Collaboration:

- Ability to work collaboratively with cross-functional teams, including engineering, production, and supply chain, to achieve quality objectives.

- Project Management:

- Skills in managing projects, setting timelines, and ensuring that quality-related tasks are completed efficiently and on schedule.

- Training and Mentoring:

- Ability to train and mentor team members on quality standards, procedures, and best practices, ensuring that everyone is aligned with quality objectives.

Tools and Technologies Used in Quality Engineering

In my role as a quality engineer, I often use essential tools such as Microsoft PowerPoint, Excel, and Word for creating presentations, analyzing data, and documenting procedures. These tools are fundamental and support a wide range of quality control tasks. Additionally, there are more advanced tools that can significantly enhance efficiency and accuracy:

- Minitab:

- Used for advanced statistical analysis, Minitab helps in identifying trends, conducting hypothesis tests, and performing quality improvement analysis.

- Power BI:

- A powerful data visualization tool that enables the creation of interactive reports and dashboards, providing valuable insights into quality metrics and performance indicators.

- Jira:

- A project management tool that supports tracking of issues, managing projects, and improving workflow efficiency. It’s particularly useful for implementing and monitoring corrective actions and process improvements.

While tools like Minitab, Power BI, and Jira are not mandatory, they are highly beneficial for streamlining processes and enhancing the overall effectiveness of quality management. Having proficiency in these tools can make a significant difference in the quality engineer’s ability to deliver high-quality results.

Certifications for Quality Engineers

There are several certifications that most companies prefer when hiring quality engineers. Key certifications include the Six Sigma Green Belt, Certified Quality Engineer (CQE), and Certified Quality Auditor (CQA). These certifications demonstrate a professional’s expertise in quality control and process improvement. The most well-known organization providing these certifications is the American Society for Quality (ASQ), which is widely accepted across various industries. Obtaining these certifications can significantly enhance your qualifications and career prospects in the field of quality engineering.

Starting Positions to Become a Quality Engineer

To become a quality engineer and advance in the field, starting with certain entry-level positions can be highly beneficial. Here are some roles that can help you get your foot in the door:

- Quality Inspector:

- This role often does not require a high level of education. As long as you have attention to detail, basic proficiency in Microsoft Office, and a willingness to learn and work hard, you can perform effectively as a quality inspector. This position involves inspecting products and materials for defects or deviations from specifications, ensuring that standards are consistently met.

- Lab Technician:

- Typically, this role requires a college degree, as it is essential for the industry and related to specific job functions. Lab technicians conduct tests and experiments, analyze results, and ensure that products meet quality and safety standards. This position provides valuable hands-on experience with testing methods and quality control processes.

- Document Controller:

- This is a critical job in quality control, responsible for managing and maintaining all quality-related documents. Document controllers ensure traceability and compliance by keeping accurate records and organizing documentation. This role requires strong organizational skills and attention to detail, ensuring that all documents are up-to-date and easily accessible.

Starting in these positions can provide you with the foundational skills and experience needed to advance to a quality engineer role. Building relationships with colleagues and supervisors, demonstrating a strong work ethic, and pursuing relevant certifications will further enhance your career prospects in quality engineering.

Job Opportunities and Growth

The demand for quality engineers is expected to remain strong across various industries. Here are some factors influencing job opportunities:

- Manufacturing and Production: As manufacturing processes become more complex, the need for quality engineers to oversee production and ensure product quality will continue to grow.

- Healthcare and Medical Devices: With increasing regulatory scrutiny, there is a significant demand for quality engineers to ensure compliance and improve product safety in healthcare and medical devices.

- Technology and Software: Quality assurance in software development and technology products is becoming increasingly critical, creating opportunities for quality engineers with expertise in software quality assurance and testing.

- Sustainability Initiatives: Companies focused on sustainable practices will require quality engineers to help implement and maintain environmentally friendly manufacturing processes.

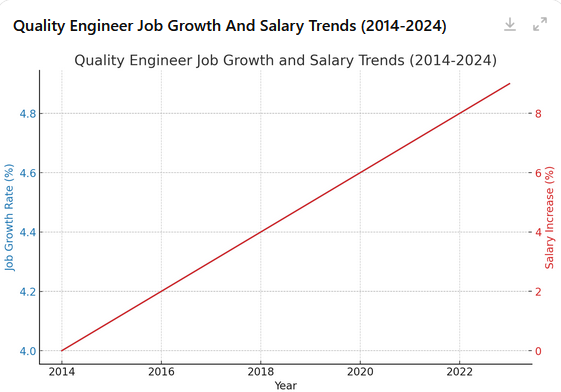

Blue Line: Represents the job growth rate percentage over the years.

Red Line: Represents the percentage increase in salaries over the same period.

This chart illustrates a steady increase in both job opportunities and salary levels for Quality Engineers, highlighting the growing demand and competitive compensation in this field.

Conclusion

The role of quality engineers is expanding, driven by technological advancements, regulatory changes, and industry-specific needs. Professionals in this field must stay updated with the latest trends and continuously enhance their skills to capitalize on the growing job opportunities. As industries evolve, the demand for skilled quality engineers will continue to rise, making it a promising career path for the future.